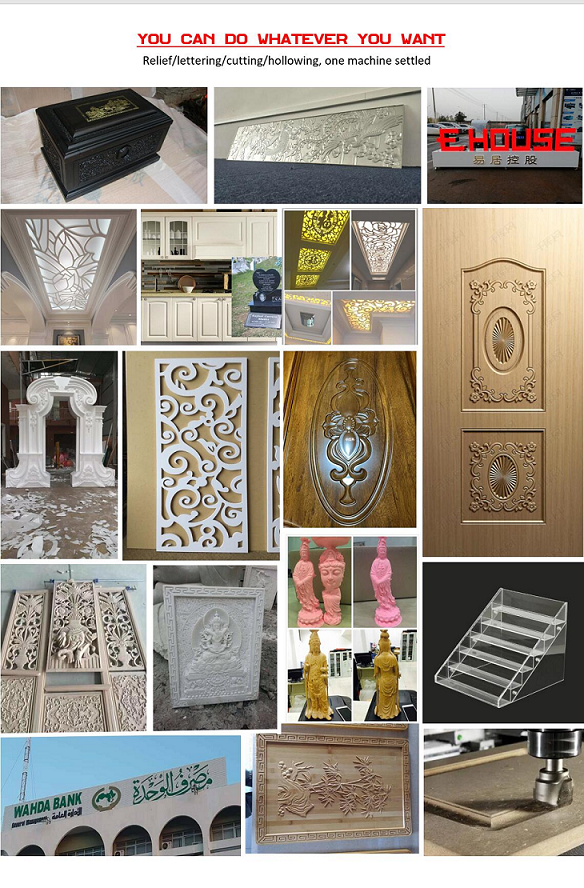

1325 CNC Router

1.Adopt heavy duty machine frame,forming by CNC planer-type milling machine,more stronger and stability.

2. High accuracy Taiwan linear guide and high accuracy helical gear and rack transmitting way.

3. Configuration with professional NC controlling system.

4. Standard configured 3KW water cooling spindle motor.

5. Be compatible with many CAD/CAM software like Type 3/Artcam/-Casmate/Pore/UG/Artgrave etc.

6. Independent control cabinet.

7. Can optional vacuum system and dust collector.

Features

1.Using Taiwan imported square linear Guide, double rows four ranks ball slider, large bearing force, smooth operation, high accuracy and long life.

2.Software compatibility, compatible with type3/Actcam/Castmate/Wentai, and other CAD/CAM design software.

3.Y axis using a dual-motor drive, speed up to 25 m/min above speed, combined with strong cutting spindle engraving speed can be improved.

4.Steel table overall.

5.This model is suitable for 2-3 flower-type knife carving and milling, various patterns of processing without tool change, automatic program execution. Its main feature is to invest less, high profits, less maintenance and easy to operate.

Technical parameters

|

Working Area(X,Y,Z) |

1300mm*2500mm*200mm |

|||

|

Perfect Laser also have the ability to custom-made according to user's special demand |

||||

|

Spindle Power |

air cooling 4.5Kw |

air cooling 6 Kw |

HSD Italy 6Kw |

HSD Italy 9Kw |

|

Spindle Cooling Way |

air cooling |

air cooling |

air cooling |

air cooling |

|

Frame Structure |

Seamless welding steel structure |

|||

|

X,Y Structure |

Square Guide Rail, Gear Transmission |

|||

|

Z Structure |

Linear guide rail, ball screw |

|||

|

Working Delicacy |

0.025-0.05mm |

|||

|

Max Engraving Speed |

25,000mm/min |

|||

|

Resolution ratio |

0.002mm |

|||

|

Repetition accuracy |

±0.02mm |

|||

|

Spindle Rotating Speed |

6000 - 24,000rpm |

|||

|

Drive motor system |

Step Motor and Step Driver(Option: Servo System) |

|||

|

Operating System |

DSP A11/Ncstudio control system |

|||

|

Working-holding |

vacuum working table |

|||

|

Dust removing plant |

Duct collection (dust prevent setup) |

|||

|

Engraving Command |

G code, u00, mmg, PLT, HPG |

|||

|

Command language system |

English Version, Windows 98/2000/XP Operation System |

|||

|

Operational Software |

Original Type3 Software, ArtCam software or Wentai Software |

|||

|

Command language system |

English Version, Windows 98/2000/XP Operation System |

|||

|

Software Compatibility |

Support CAD/CAM software, PLT format, Corel Draw, Auto CAD |

|||

|

Working temperature |

0-45°C |

|||

|

Relative humidity |

30% - 75% |

|||