Automatic Edge banding Machine

Edge thickness 0.4-3mm

Edge width 12-62mm

Workpiece thickness 10-60mm

Heating power 2kw

Pre-heating power 350w

Conveyor belt 1.5KW

Glue power 0.75KW

End cutting 0.37kw*2,12000r/min

Rough milling 0.75kw*2,12000r/min

Fine milling 0.75kw*2,18000r/min

Corner trimming 0.75kw*2

Buffing 0.37w*2,1350r/min

Feeding speed 12-20m/min

Working pressure 0.7Mpa

Total power 12kw

Features

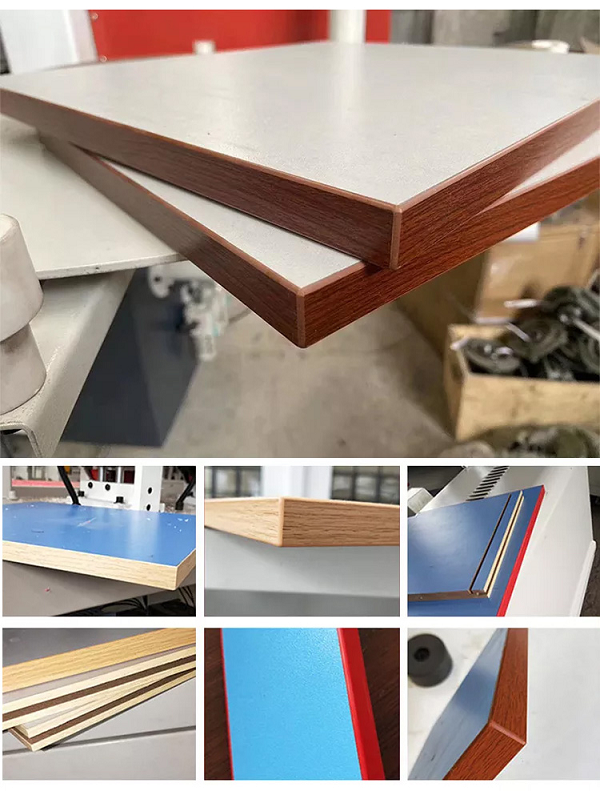

1.Through special structure, the edge-sealing sheet and the edge-sealing material are evenly coated and pressed, so that the edge-sealing strip is more firmly attached.

2.Through the precision linear guide motion, the rapid cutting structure of the high-frequency high-speed motor is automatically tracked by the master to ensure that the cut surface is smooth and smooth.

3.Rough trimming and fine trimming,ensure that the upper and lower plates are smoother and more tidy when trimming.

4.Used to eliminate the ripples caused by the cutting process of trimming non-linear motion.

5.Clean the finished plate with a cotton polishing wheel and smooth the edge of the edge by polishing.

automatic edge banding machine function

gluing and pressing-end cutting-rough trimming-fine trimming-scraping- buffing

| model no | AS506 |

| name | automatic edge banding machine |

| motor power | 9.2kw |

| feeding speed | 12-20m/min |

| working thickness | 10-60mm |

| edge band thickness | 0.4-3mm |

| working air pressure | 0.8mpa |

| working width | ≥40mm |

| weight | 1900kg |

| overall dimensions | 4150mm*1100mm*1600mm |