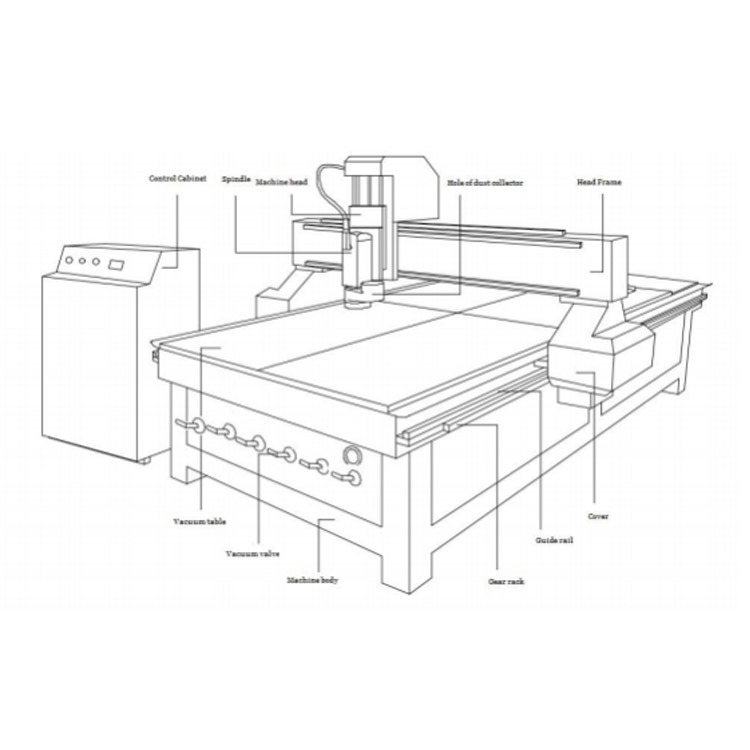

A CNC router machine is made up of four main components as described below:

- Bed: The bed is the area where the raw stock is mounted. Some beds will have multiple holes or attachment points to make it easier to mount clamping hardware to keep the raw stock fixed in place during the cutting operations.

- Controller: The controls typically consist of multiple stepper controller drives to control the motion of the stepper motors and the speed of the spindle/router.

- Motors: A CNC router machine has a stepper or servo motor for each of the three motion axes. Stepper motors are typically found on cheaper hobbyist machines whereas servos provide better positioning precision and are more expensive. A separate high-speed motor rotates the cutting tool.

- Spindle/Router: The spindle is what is used to rotate the cutting tool to the required operating speed. The spindle is often mounted on a gantry above the bed. This gantry can move left and right along the x-axis and back and forth on the y-axis.